MINING & MINERAL PROCESSING

Helford Geoscience are at the forefront in the application of automated mineralogy

in the mining and minerals industry

Helford Geoscience our experience

Helford Geoscience have years of experience in the characterisation of the mineralogy of exploration

samples, mineral processing products and tailings

Helford Geoscience

Mining and Mineral Processing

Understanding the mineralogy of an ore deposit is critical during the complete

life cycle of an operation through exploration, production and eventual closure. Detailed mineralogical studies are critical in ensuring maximum recovery in a cost effective manner. Understanding the distribution, abundance, size, mineralogical associations, liberation characteristics and chemistry of the ore phases is critical.

Traditional mineralogical tools such as reflected light microscopy, have largely been superseded by automated mineralogy, where in a mineral processing product, thousands of particles can be mapped providing rigorous mineralogical datasets. Helford Geoscience have experience in tailoring automated mineralogy solutions to many ore types including Cu, Pb, Zn, Fe, Al, Ti, Sn, W, REE, Au, Ag and PGM along with industrial mineral products such as fluorspar, silica sands

and clay minerals.

Mining & mineral processing capability

Helford Geoscience

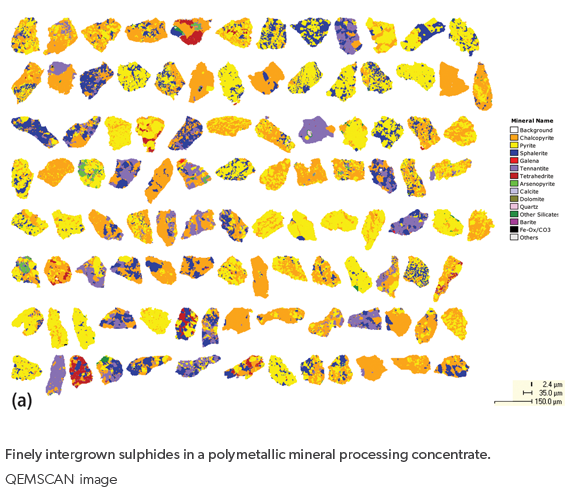

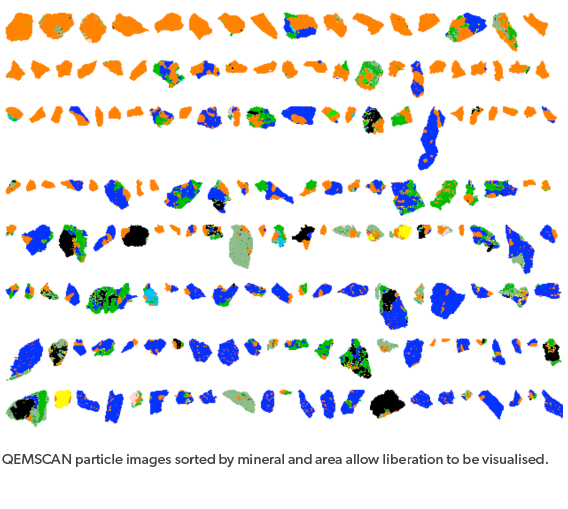

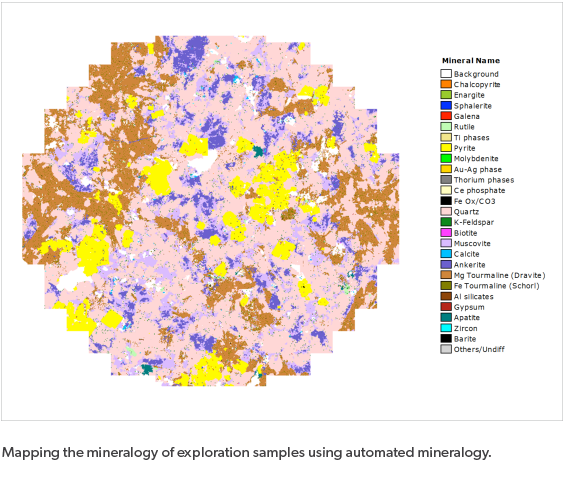

QEMSCAN analysis

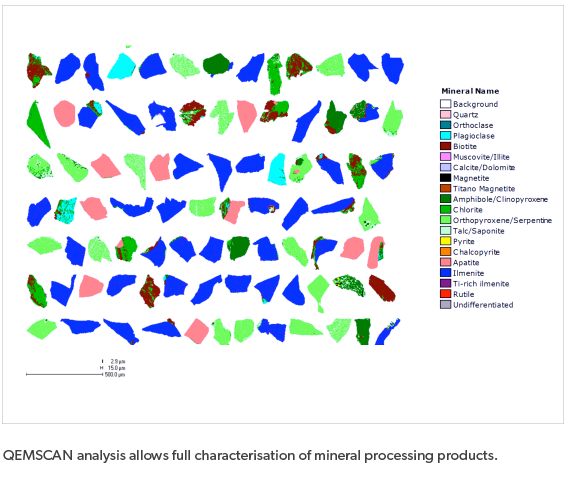

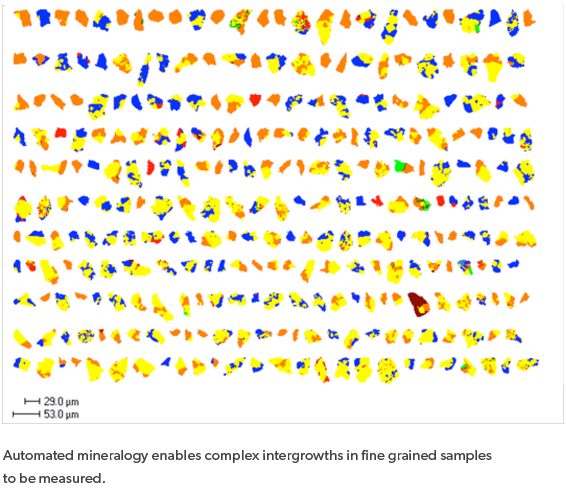

Automated mineralogy using QEMSCAN technology has revolutionised the analysis of ore deposits and mineral processing products. The ability to automatically analyse the mineralogy of mineral processing products and in a single analysis quantify the modal mineralogy, calculated assay, grain size, liberation characteristics, mineral associations and theoretical grade recovery

is invaluable in improving plant efficiency and ore recovery. This combined with

the ability to quantify thousands of particles means that automated mineralogy

is today an essential part of any modern mineral processing operation.

The analysis is however complex, and experience in sample preparation, measurement parameters and post-measurement data processing is critical

for data QC. With many years experience in automated mineralogy Helford Geoscience can tailor your analyses to address the critical questions you

need to answer.

Mining & mineral processing capability

Helford Geoscience

Mineral Processing

Ensuring maximum cost-effective mineral recovery is critical for all mineral processing plants. Automated mineralogy provides the robust datasets on which operational decisions can be made.

Helford Geoscience have carried out hundreds of mineral analysis projects for

our international client-base on a wide range of commodities including Cu, Pb, Zn, Fe, Al, Ti, Sn, W, REE, Au, Ag, PGM along with industrial mineral products such as fluorspar, silica sands and clay minerals.

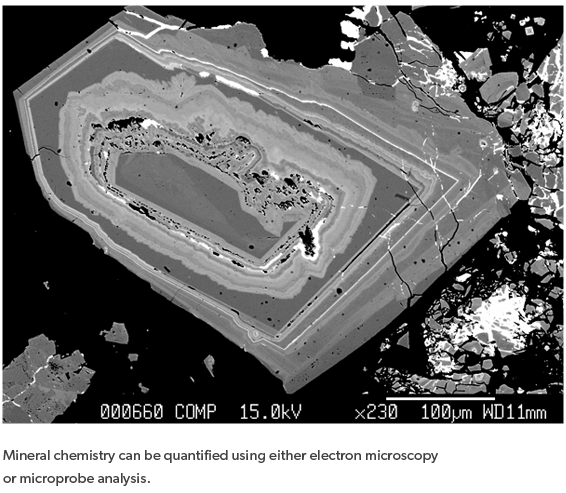

Helford Geoscience can provide a tailor-made analytical solution, ensuring the highest quality data sets typically with a rapid turn-around time from sample receipt to full reporting. Data outputs typically comprise mineral mass %, grain size, liberation, mineral association and theoretical grade recovery. Mineral and sample chemistry can also be quantified.

Mining & mineral processing capability

Helford Geoscience

Exploration

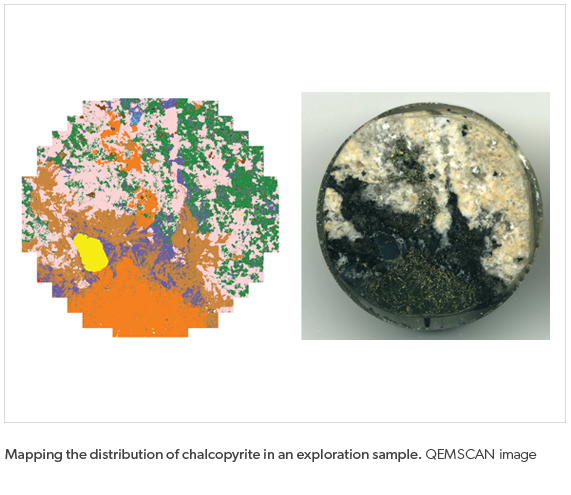

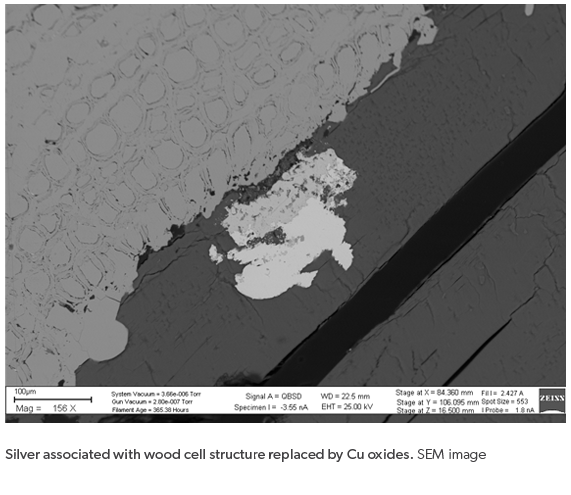

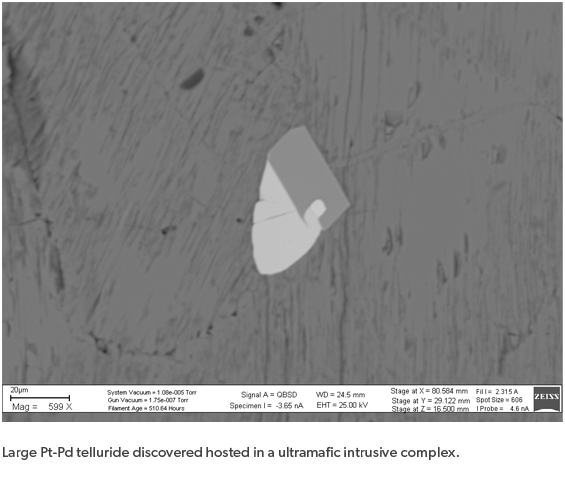

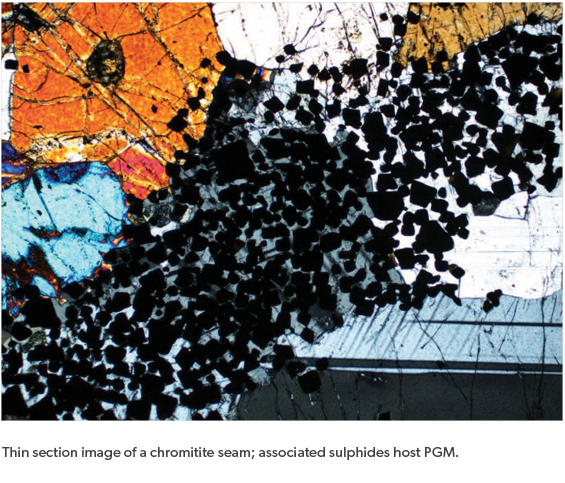

Detailed mineralogical understanding of ore deposits is an essential stage in any mineral exploration programme. Helford Geoscience have previously published on the discovery of a range of ore deposits ranging from platinum group mineralisation hosted within mafic and ultramafic intrusive complexes through to Cu and Ag mineralisation hosted within red bed sediments.

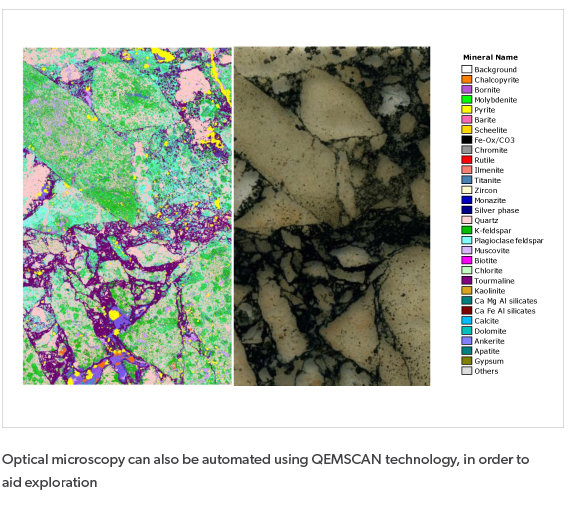

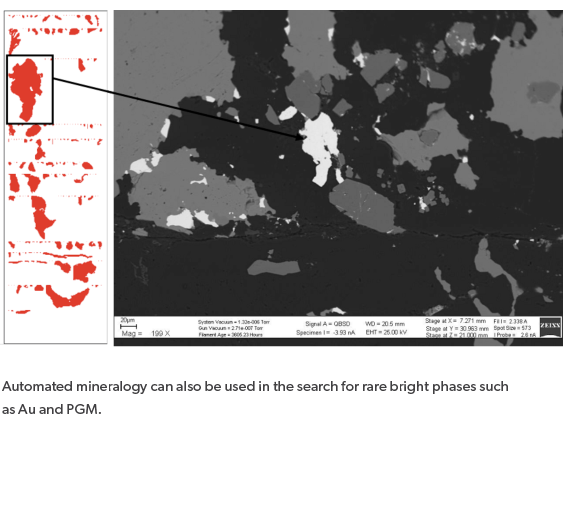

We can provide detailed mineralogical analysis on samples from outcrop or core, including thin section preparation, optical microscopy, scanning electron microscopy and automated mineral analysis based on QEMSCAN technology. Automated mineral analysis is also ideally suited for the search of rare “bright” phases such as Au, Ag and PGM.